- #Siemens step 7 manager print rungs with cross refernces serial

- #Siemens step 7 manager print rungs with cross refernces software

- #Siemens step 7 manager print rungs with cross refernces Offline

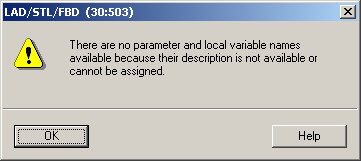

In the "Project Name" field, type in your project name. Select "LAD" as the language for the OB1 block.

The easiest way to start a new project is to use the "New project" wizard: Select from the program menu, File 'New Project' wizard Click on Next>.

If you are starting a new project and a project is displayed in the window, close it by clicking on the red "X".

#Siemens step 7 manager print rungs with cross refernces software

Start the Step 7 software by clicking on the SIMATIC STEP 7 icon on the desktop, or by selecting Start All Programs SIMATIC SIMATIC Manager A project window should appear with a list of selections.

#Siemens step 7 manager print rungs with cross refernces serial

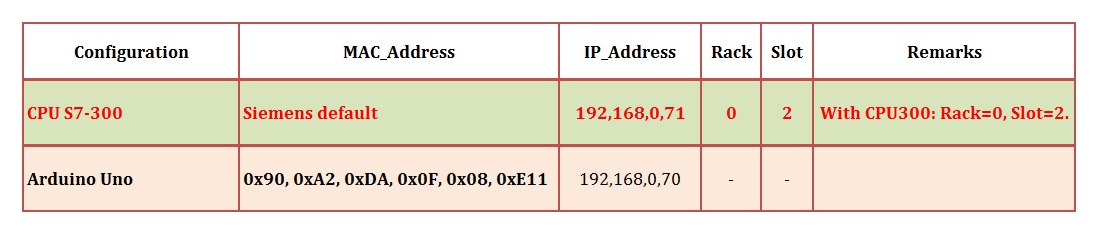

Since the PC serial port is used to connect to the processor, the RSLinx AB_DF1 driver must be stopped before Step7 will be able to connect to the processor. Make sure the computer, PLC, and external power supply are all powered. Turn the key on the PLC processor to the RUN-P position. Power up the computer, the PLC rack, and external power supply, as needed. STARTING A PROJECT WITH THE S7-400 Wire the switch/light board before proceeding. The PLC and the PC used to program it are connected directly through a serial RS-232 link.ĥ Step7_400-3 A. An icon for these programs should already be on the desktop. Siemens Step 7 version 5.4 is used to program the S7-300 and S7-400 PLCs. For these labs, the ladder programming will be done online so that changes can be immediately tested. In addition, there is usually only one project (program) for each PLC on the network.

#Siemens step 7 manager print rungs with cross refernces Offline

In an industrial setting, the initial PLC programming is done offline and then later downloaded to the PLC when ready for the final test and debug. The remainder of the sections outline the steps to document your ladder, to print the ladder logic program, and to save your ladder logic diagram. In order to become familiar with basic ladder logic programming and addressing techniques on the Siemens equipment, the steps to accomplish the first part of the first lab exercise are outlined in sections A and B. A SERIAL COMM MODULE serial cable connection from the PC to the processor is also assumed. out/0.5a This document is primarily for version 5.4 of the Step7 software. Module Profibus network to an ET200M rack with the following modules: Siemens 6ES BA00-0XB0 IM interface module Siemens 6ES BL00 32 chan.

The following equipment is assumed: Siemens 6ES KA01-0AA0 PS407 10A power supply Siemens 6ES XL00-0AB0 CPU417-4 (Rev 3.0) processor Siemens 6ES7 6GK EX10-0XE0 CP (Rev 2.3) Ethernet comm. Printing Ladder Logic Program Step7_400 15Ĥ Step7-2 This document is a supplement to the Lab 1.doc lab exercise that introduces one to the basics of ladder logic programming. Adding Comments to Ladder Logic Step7_ D. Ladder Logic Programming Step7_ Two Contacts in Series (Logical AND) Step7_ Entering Branches (Logical OR) Step7_ Timers Step7_ Counters Step7_ C. Starting a Project With the S7-400 Step7_ Configuring Communications Step7_ Rack Configuration Step7_ Specifying Other Variables Step7_ Processor Download Step7_400 7 B. The student will spend the last hour of the class using what was learned to troubleshoot an actual faulted PLC system.Ĭourse Length & Time: Three days.1 Step7_400-1 Siemens Step 7 S7-400 Programmingģ Step7_400-1 Table of Contents Page A. The class focuses on maintaining & troubleshooting the S7 PLC using Step 7. This three day course assumes the student has a very basic understanding of PLCs and will introduce students to the Step 7 software package, used to program and maintain the S7-300/400 PLC systems.

0 kommentar(er)

0 kommentar(er)